Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!

Welcome to Shanghai Zhongyou Industrial Co., LTD. Website! Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!

Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!Current Location:首页 > Product center > Dehumidification air conditioner for underground civil air defense works > Air conditioning dehumidification unit for civil air defense > CK25-DX air conditioning dehumidifier for underground engineering

Brief description:Air conditioning dehumidifier for underground engineering

Specification: CK25-DX

Dehumidification capacity: 90kg/h

Product features: This series of products uses a new design concept, tailored to the thermal and wet load characteristics of underground engineering

Product model:CK25-DX

Product model:CK25-DX Nature of manufacturer:manufacturer

Nature of manufacturer:manufacturer Update time:2024-05-15

Update time:2024-05-15 Number of enquiries: 1099

Number of enquiries: 1099Product classification

Product CategoryRelated article

Related ArticlesDetailed introduction

| 品牌 | ZHONGYOU/ Zhongyou | Application type | Other dehumidifiers |

|---|---|---|---|

| Price range | 5万-10万 | Type of instrument | Dehumidifier (with compressor) |

| Category of origin | 国产 |

Unit profile:

Dehumidification air conditioner for underground engineering is our company set more than 40 years of professional design and manufacturing experience of air conditioning dehumidification equipment,Through a large number of data collection and analysis,For underground engineering or similar underground engineering use environment,This new type of dehumidification air conditioning equipment has been developed in series,Applicable to *, civil air defense projects, subway stations, space bases, underground shopping malls, underground entertainment centers and other places that have both general air conditioning and dehumidification requirements。

This series of products uses a new design concept,Customized for the thermal and wet load characteristics of underground engineering, And adopted a large number of new materials, new technologies and new processes,The unit also has two functions of central air conditioner and dehumidifier,Truly realize a multi-purpose machine,All performance indicators *,It is called the pioneer of energy conservation and environmental protection in the new era。

How it works:

The operation of the dehumidifier system consists of the internal circulation of the dehumidifier (refrigerant circulation system) and the external circulation of the dehumidifier (air circulation system).

The internal cycle of the dehumidifier: through the operation of the compressor → discharge of high temperature and high pressure gas from the exhaust port → cooling into the condenser → becoming low temperature and high pressure gas → intercepting through the capillary → becoming low temperature and low pressure liquid → evaporating through the evaporator → returning to the compressor to become low temperature and low pressure gas, and so on。

The external circulation of the dehumidifier: in the case of normal startup → through the operation of the fan → the humid air is drawn from the inlet → through the evaporator → the evaporator adsorbs the water in the air on the aluminum sheet → becomes dry air (→ heat dissipation through the condenser)→ blows out from the outlet。

Unit features:

1. Multiple functions, one machine multi-purpose:

The unit has good engineering adaptability and can realize three operating modes of air conditioning, dehumidification and dehumidification temperature control。The unit operates at full load in air conditioning mode,The internal waste heat can be effectively eliminated,The goal is to reduce the air temperature,Suitable for the period of large engineering thermal coincidence;The unit operates at partial load in dehumidification mode,Mainly used for dehumidification,It is used in the period of small residual heat and large residual humidity,It can be adjusted with the equipment,Achieve low air volume operation,Ensure that the relative humidity in the project meets the requirements,Especially suitable for underground engineering maintenance management operation;The unit operates at full load in dehumidification and temperature control mode,Suitable for underground engineering maintenance management operation;The unit operates at full load in dehumidification and temperature control mode,It is suitable for the operation of peacetime combined engineering in the transition season and under the condition of small residual heat and large residual temperature,Can effectively eliminate indoor residual temperature。

2. Energy efficient operation - Heat recovery:

The condensation heat is used as the secondary heating source of the air conditioner, which reduces the operating cost of the unit, saves the operating energy consumption, and improves the energy-saving index of the unit。

3. Structure type "personalized" :

Dehumidification air conditioner for underground engineering adopts modular design concept and combined structure, which is composed of mixed air filtration section, cooling and reheating section, air supply section and main engine section。Free assembly, simple connection, easy disassembly。

4. Energy regulation:

The unit uses high-performance screw compressors or scroll compressors to achieve a variety of operating modes by stage adjustment, and at the same time, the variable speed fan and the compressor's energy regulation are combined。

5. Direct evaporation, efficient refrigeration:

The unit is a multi-functional combined dehumidification air conditioning equipment with its own cold source (direct evaporation type),Set refrigeration system, ventilation system and control system in one,Compared with units using chilled water as secondary refrigerant,Simple and efficient,Increase efficiency by more than 10%;Evaporator layout design,Make full use of the evaporator area,At 50% load,Evaporator efficiency increased by more than 30%,High refrigeration efficiency。The unit is easy to install, and can be run only by wiring and taking over on site。

6. Compressor and cold:

The compressor and the main refrigeration accessories are all famous products, through the scientific and reasonable optimization design of the refrigeration system, the unit has low noise, reliable operation and high energy efficiency ratio。

7. Heat exchanger:

The water side heat exchanger is shell and tube heat exchanger with high efficiency heat exchange tube.The air side heat exchanger is a copper tube with aluminum fin type heat exchanger, which is manufactured by OAK heat exchanger production line in the United States。The heat exchanger has compact structure, good pressure and high heat exchange efficiency。

8. Environmental protection working medium, "green" concept:

The unit uses R22 refrigerant that meets the requirements of the national program for the elimination of CFC working medium, which is beneficial to the earth environment。The company can also customize the dehumidifier with HFC working medium such as R407C and R134a according to user requirements。

9. 外壳:

The unit adopts high strength aluminum profile frame which is popular at home and abroad.The disassembly and bending parts are processed by Japanese AMADA CNC equipment with excellent appearance quality。The unit adopts assembled structure, the overall structure is compact, beautiful and generous, and rich modern flavor。

10. Full automatic control:

The unit fully applies modern control technology, optimizes the control model, adopts a good PLC as the control system, has its own control cabinet, ensures the control accuracy, and realizes the mechanical and electrical integration。The unit is equipped with a friendly and simple all-Chinese man-machine interface, the standard configuration is text display, and the touch screen can also be used according to user requirements。

11. Optional network features:

The unit can connect the device to a remote computer via a modem or Ethernet module,Use the INTERNET for data exchange,Remote monitoring and fault analysis of the unit,Help you predict and troubleshoot quickly and accurately,The group control function of LAN units can also be realized by PROFIBUS。

12. Multiple protection:

The unit is equipped with overload, short circuit, lack of phase, overheating, high and low pressure protection, as well as fan, water pump, fire valve chain protection。

13. Function segment description:

Mixed air filter section: the fresh air and return air are mixed, and the mixed air is filtered, which mainly includes the fresh air flange, the return air flange and the initial effect filter。

Cooling and reheating section: corresponding heat and humidity treatment of air, mainly including evaporator and air-cooled condenser。

Air supply section: the treated air is transported to the destination, which mainly includes variable speed fans and shock absorption devices, and the air outlet mode is upper air。

Main engine segment: The refrigeration working medium is compressed and condensed, which is mainly composed of refrigeration components such as compressors and water-cooled condensers and electrical control systems (including fans for type I machines).。

Other: The company can also add intermediate filter segment, intermediate segment and other auxiliary function segment according to the actual needs of users to meet the air treatment needs of different occasions。

说明:

The air inlet modes are as follows: Facing the controller, the air inlet is left when the return air outlet is on the left, and the air inlet is right when the return air outlet is on the right.

The cooling water inlet and outlet of this series of units are distributed on different sides from the controller, that is, the controller is on the front and the cooling water inlet and outlet is on the back。

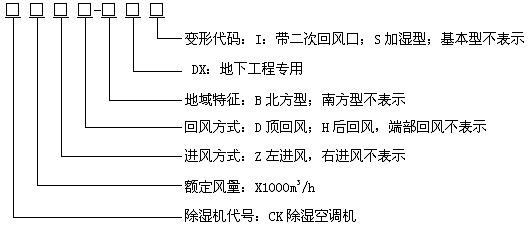

Model example: CK12-DX indicates a dehumidification air conditioner for underground engineering in the south with nominal air volume of 12000m3/h and return air mode of end return air. It faces the unit controller and the return air outlet is on the right。

Southern Type - Basic type performance parameter table:

Product consulting

Scan wechat